Central vacuum cleaning system

|  |

The central vacuum system's vacuum host is far away from the production area, making the environment in the production area more comfortable and quiet, and avoiding secondary pollution caused by the exhaust emissions of the vacuum cleaner. It can send various dusts, germs and other particles through the dust collection pipe buried in the wall to the vacuum host far away from the production area, truly cleaning your work space. The central vacuum system that is comfortable, simple, clean, quiet, powerful and gets twice the result with half the effort is your wise choice! Central vacuum systems have five times the suction power of ordinary vacuum cleaners. The dust collection efficiency is 5-8 times that of traditional stand-alone vacuum cleaners, and the filtration efficiency for particles >0.3 microns is as high as 97%.

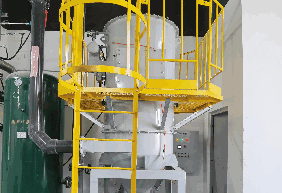

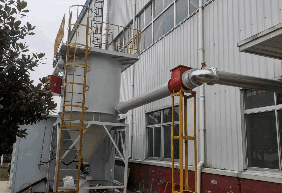

The main job of the vacuum cleaner is to evacuate the inside of the barrel through a Roots blower, causing the negative pressure to rise rapidly. The high negative pressure causes the air to quickly flow into the inside of the barrel through the air inlet. Through the vacuum brush and vacuum tube, the flowing air carries the solid particles that need to be collected and processed into the rotating In the separation chamber, after the dust-containing airflow enters the dust collector from the tangential inlet, the airflow rotates in the dust collector. The dust particles in the airflow move toward the outer wall under the action of centrifugal force, reach the wall, and fall along the wall into the ash hopper under the action of airflow and gravity to achieve the purpose of pre-separation of large particles.

The initially filtered gas rises, and the remaining dust will be attached to the inner surface of the filter bag. After secondary filtration by the filter element, the air can reach the emission standard. The filtered air enters the exhaust duct through the exhaust port of the fan or air pump, and is finally discharged. The filtered dust particles are collected into the dust collection bucket at the bottom of the vacuum main unit through rotational separation and pulse cleaning to complete the collection of dust particles.

"Cartridge Dust Collector" (JB/T 10341-2002)

"Comprehensive Emission Standards for Air Pollutants" (GB16297-1996)

"Design Code for Power Distribution of General Electrical Equipment" (GB50055-93)

"Technical Performance and Test Methods of Dust Removal Units" (GB/T 11653-2000)

"Steel surface corrosion grade and rust removal grade before painting" (GB 8923-88)

Modular design:Modular design provides higher flexibility. You can increase the filtration capacity of the equipment by adding modules;

Save floor space:The pleated cartridge filter element is small in size and has a large filtering area. It is easier and more convenient to install the filter element horizontally and replace it;

Downward airflow design:Effectively improves the collection rate of smaller and lighter dust, helps cleaning the filter material, and extends the service life of the filter material;

Timing high pressure air backwash:The backwash frequency can be set according to the dust characteristics and dust content to reduce the dust load on the filter material and save high-pressure air.

Filter media pressure difference display:The usage status of the filter material can be grasped to facilitate the prevention of clogging of the filter material and maintenance work.As a basis for filter material cleaning or renewal;

Enhanced filter material cleaning function:After the fan stops running, the dust removal equipment can be set to delay cleaning, so that when it is turned on again, the system can maintain good performance and extend its service life;

Waterproof and dustproof solenoid valve group:The solenoid valve complies with IP65 and NEMA4 and is not afraid of wind and rain, ensuring the normal operation of the dust removal equipment in bad weather;

Closed dust bin:Commercially available garbage bags are installed inside to avoid the trouble of dust re-overflow, and the garbage bags can be replaced without shutting down the machine;

Various filter media options:Different filter materials can be selected according to different working conditions;

Differential pressure gauge, pulse solenoid valve, ladder platform, pressure regulating valve, pulse controller

Fans, manual gate valves, rotating unloading valves, spark arresters, explosion-proof and explosion-proof devices, fire extinguishing systems, online dust detectors, movable storage

Ash bucket, screw conveyor, integrated high-efficiency filter, PLC touch screen control, network remote control and dust collector filter material;

Next article:Mobile drag and drop vacuum cleaning equipment

Current location:

Current location: