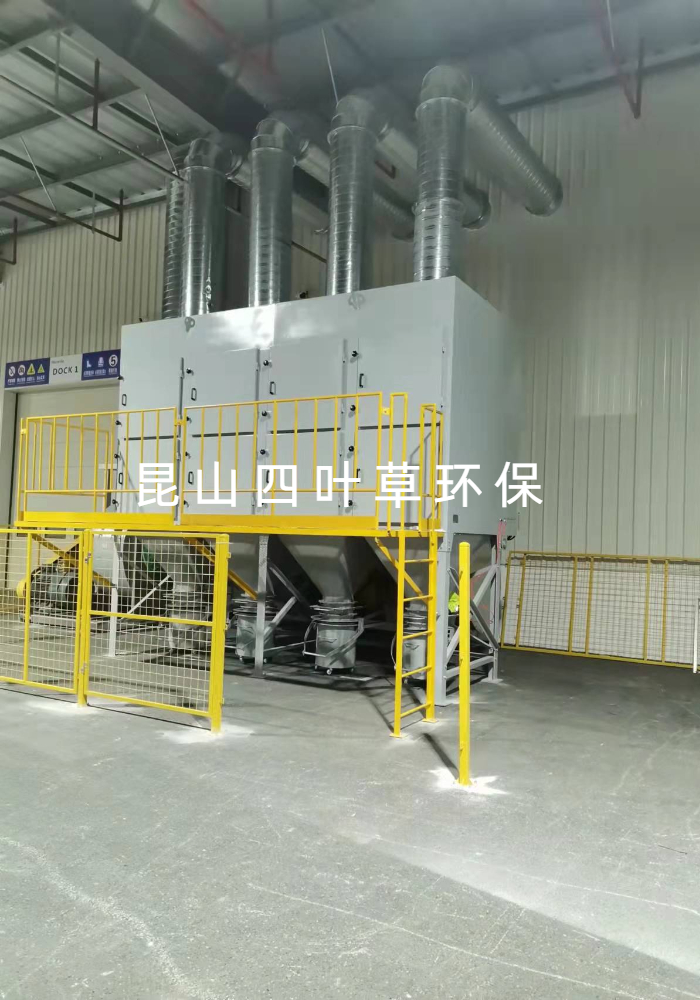

Horizontal filter cartridge dust collector

|  |

Pulse cartridge dust collectors are divided into horizontal cartridge dust collectors and vertical cartridge dust collectors according to the assembly method of the filter element. In the industry, they are also called downflow cartridge dust collectors, oblique insertion cartridge dust collectors, magazine cartridge dust collectors, dust collectors, dust collectors, etc.; dust collectors that use the filter element (filter cartridge) as the core filtration unit and use electromagnetic pulse valves to control compressed air dust cleaning operations;

During normal operation, dust-containing gas enters the dust collector from the top or side and passes through the filter cartridge. At this time, the dust is trapped on the outer surface of the filter cartridge, and the clean air enters the clean air chamber through the center of the filter cartridge and is discharged through the outlet; during pulse cleaning, the pulse controller will clean a group of filter materials according to the preset time or differential pressure value. At this time, the pulse controller will control a pulse solenoid valve to open, and the high-pressure air in the air storage bag will instantly enter the center of the filter cartridge to blow away the dust trapped on the surface of the filter cartridge. Driven by the main air flow and the dust's own weight, the dust flows downward into the dust collecting hopper of the dust collector;

"Cartridge Dust Collector" (JB/T 10341-2002)

"Comprehensive Emission Standards for Air Pollutants" (GB16297-1996)

"Design Code for Power Distribution of General Electrical Equipment" (GB50055-93)

"Technical Performance and Test Methods of Dust Removal Units" (GB/T 11653-2000)

"Steel surface corrosion grade and rust removal grade before painting" (GB 8923-88)

Modular design:Modular design provides higher flexibility. You can increase the filtration capacity of the equipment by adding modules;

Save floor space:The pleated cartridge filter element is small in size and has a large filtering area. It is easier and more convenient to install the filter element horizontally and replace it;

Downward airflow design:Effectively improves the collection rate of smaller and lighter dust, helps cleaning the filter material, and extends the service life of the filter material;

Timing high pressure air backwash:The backwash frequency can be set according to the dust characteristics and dust content to reduce the dust load on the filter material and save high-pressure air.

Filter media pressure difference display:The usage status of the filter material can be grasped to facilitate the prevention of clogging of the filter material and maintenance work.As a basis for filter material cleaning or renewal;

Enhanced filter material cleaning function:After the fan stops running, the dust removal equipment can be set to delay cleaning, so that when it is turned on again, the system can maintain good performance and extend its service life;

Waterproof and dustproof solenoid valve group:The solenoid valve complies with IP65 and NEMA4 and is not afraid of wind and rain, ensuring the normal operation of the dust removal equipment in bad weather;

Closed dust bin:Commercially available garbage bags are installed inside to avoid the trouble of dust re-overflow, and the garbage bags can be replaced without shutting down the machine;

Various filter media options:Different filter materials can be selected according to different working conditions;

Differential pressure gauge, pulse solenoid valve, ladder platform, pressure regulating valve, pulse controller

Fans, manual gate valves, rotating unloading valves, spark arresters, explosion-proof and explosion-proof devices, fire extinguishing systems, online dust detectors, movable storage

Ash bucket, screw conveyor, integrated high-efficiency filter, PLC touch screen control, network remote control and dust collector filter material;

Next article:Vertical filter cartridge dust collector

Current location:

Current location: