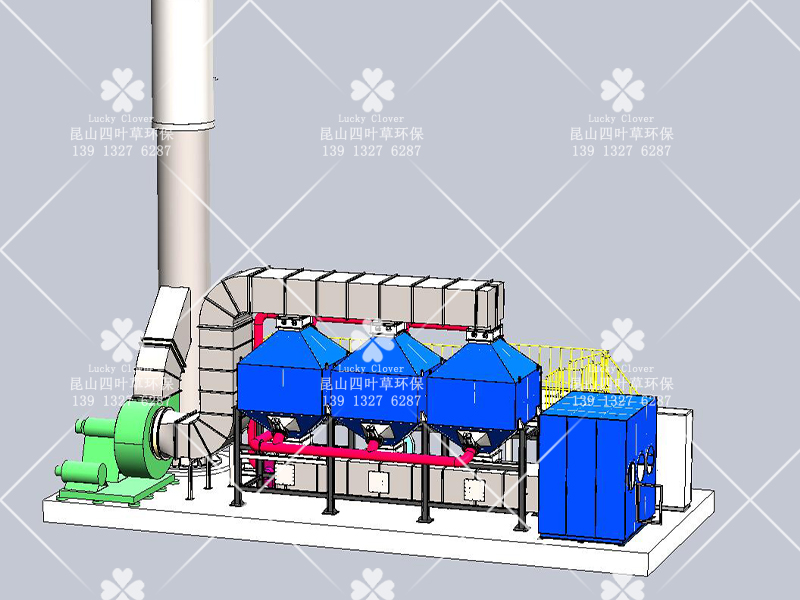

Adsorption concentration + catalytic combustion equipment

|

|

The adsorption concentration-catalytic combustion method combines the advantages of the adsorption method and the catalytic combustion method. It uses a new adsorption material (honeycomb activated carbon) for adsorption. After it is nearly saturated, hot air is introduced for desorption and desorption. After desorption, the exhaust gas is introduced into the catalytic combustion bed for flameless combustion to completely purify it. The hot gas is recycled in the system, greatly reducing energy consumption. This method has the advantages of stable and reliable operation, low operating cost, and convenient maintenance, and is suitable for waste gas treatment with large air volume and low concentration. However, the investment cost of this program is relatively high.

The process flow of this device is: pretreatment; adsorption and concentration; desorption and desorption; catalytic combustion process. The system consists of N activated carbon adsorption boxes (N-1 suction and 1 desorption) and 1 catalytic combustion bed. All exhaust pipes in each production line are merged and connected to the purification equipment. A manual regulating valve is installed on each branch pipe to adjust the air volume in proportion; a set of exhaust pipes is installed between the adsorption purification device and the exhaust gas inlet. Pretreatment spray + dry filter to filter dust to avoid clogging of activated carbon pores, and then send it to the activated carbon adsorption box for adsorption and purification. When the activated carbon adsorber is close to saturation, use hot air flow to analyze and desorb the saturated activated carbon adsorption box to desorb organic matter from the activated carbon. During the desorption process, the organic waste gas has been concentrated, and the concentration after concentration has increased dozens of times compared with the original concentration, reaching more than 2000 mg/m3. The concentrated waste gas is sent to the catalytic combustion device for oxidation and decomposition, and is finally decomposed into CO2 and H2O and discharged. After completing the desorption and desorption, the system automatically switches back, and the finally purified clean gas is discharged into the atmosphere by the main exhaust fan.

"Technical Specifications for Industrial Organic Waste Gas Treatment Engineering by Adsorption Method" (HJ 2026-2013)

"Technical Requirements for Environmental Protection Products Catalytic Purification Devices for Industrial Organic Waste Gases" (HJ T 389-2007)

"Technical Specifications for Industrial Organic Waste Gas Treatment Engineering by Catalytic Combustion Method" (HJ 2027-2013)

"Comprehensive Emission Standards for Air Pollutants" (GB16297-1996)

"Design Code for Power Distribution of General Electrical Equipment" (GB50055-93)

"Technical Performance and Test Methods of Dust Removal Units" (GB/T 11653-2000)

"Steel surface corrosion grade and rust removal grade before painting" (GB 8923-88)

1) The entire system equipment realizes the automation of the purification and desorption process. Compared with the recycling organic waste gas purification device, it does not need to be equipped with additional energy such as compressed air. The operation process does not produce secondary pollution, and the equipment investment and operating costs are low;

2) Use a filter in front of the activated carbon adsorption bed to filter small particles, which has high purification efficiency and ensures the service life of the adsorption device.

3) Use specially formed honeycomb activated carbon as the adsorption material. Since its specific gravity is 8-10 times that of strip activated carbon fibers, the adsorbed organic solvent before regeneration can reach 25% of the total weight of the activated carbon. It has the characteristics of long service life, low operating resistance of the adsorption system, and high purification efficiency;

4) The equipment occupies a small area and is light in weight. The adsorption bed filter material adopts a stacked structure, which is easy to load and replace;

5) Using high-quality precious metals palladium and platinum supported on honeycomb ceramics as catalysts, it has the characteristics of low resistance, high activity, long service life, low decomposition temperature, short desorption preheating time, low energy consumption, and good stability. When the concentration of organic waste gas reaches 2000ppm, spontaneous combustion can be maintained. The catalytic burner has high conversion efficiency and stable performance. The catalytic combustion rate reaches over 97%.

6) Use waste heat to save energy. The desorption and desorption of activated carbon in this device uses hot air as the desorption medium, and this hot air flow comes from the waste heat after catalytic combustion in the system. The desorbed concentrated organic waste gas then enters the catalytic burner for purification treatment. No additional energy is required, and operating costs are greatly reduced.

7) Using PLC control system, the equipment operation and operation process are automated, and the operation process is safe, stable and reliable. For example, the catalytic combustion heating part is automatic, and the desorption process is automatically programmed. During desorption, the temperature signal feedback is used to realize automatic control of the desorption temperature.

Adsorption device:It consists of exhaust gas pipeline, dry filter, activated carbon adsorption box, pneumatic and electric regulating valves, catalytic purification device, flame arrester, mixed flow heat exchange device, exhaust fan, electrical control and other parts.

Catalytic purification device:It is composed of flame arrester, mixed flow heat exchange device, exhaust fan, electrical control and other parts.

PLC touch screen control, network remote control, etc.

Next article:Activated carbon adsorption tower

Current location:

Current location: