Jet type Venturi wet dust collector

|  |

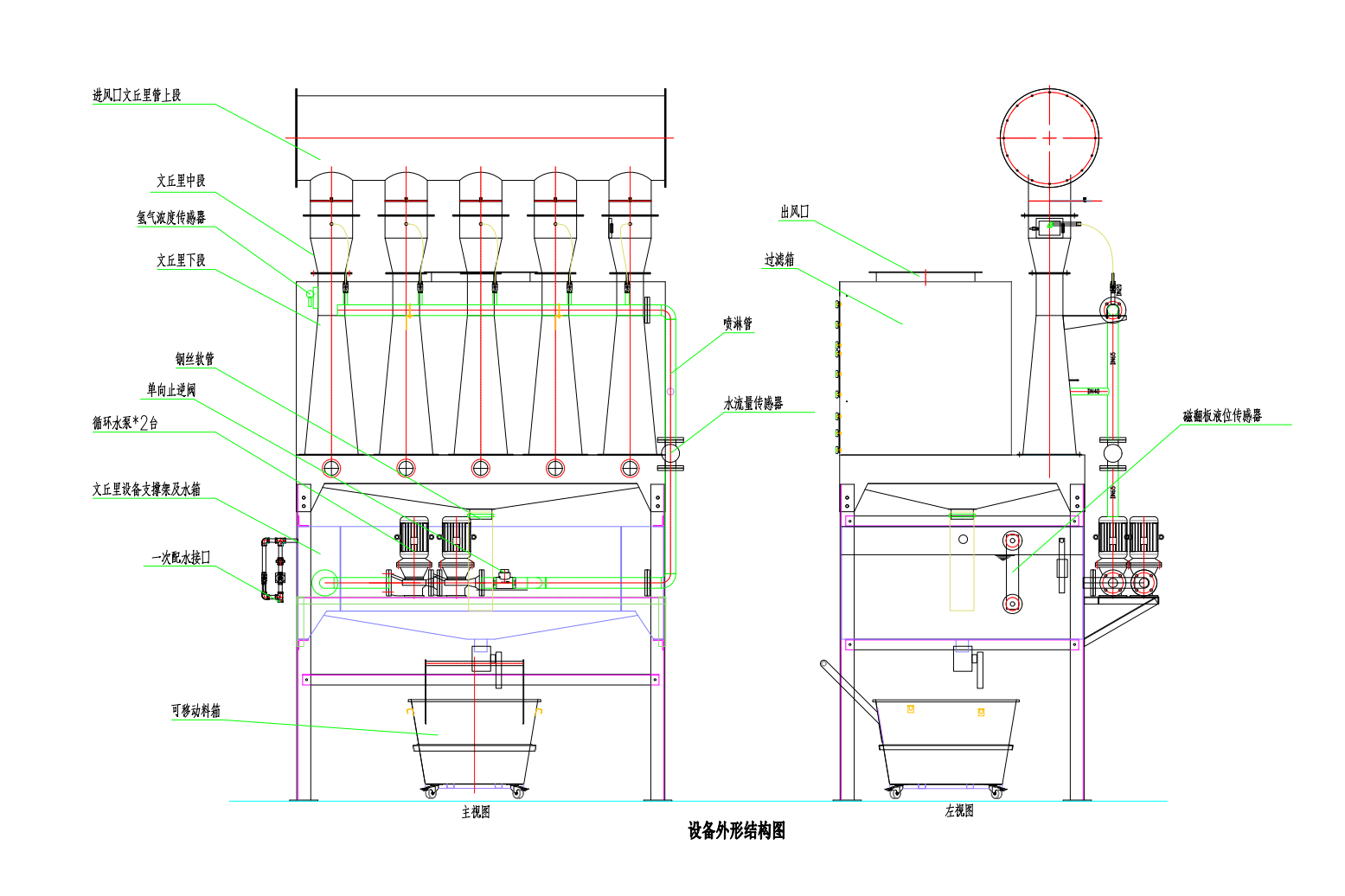

Jet Venturi wet dust collector, also known as Venturi scrubber. Venturi dust collector is a device that brings dust-containing gas into close contact with liquid (usually water) and uses the inertial collision of water droplets and particles and other effects to capture particles or increase their size. It is mainly composed of a Venturi tube (which has three parts: a shrink tube, a throat tube and an expanding tube) and a cyclone separator. Its advantages are simple structure and high dust removal efficiency. The disadvantage is that the resistance is large and it cannot be used to purify gases that are not allowed to come into contact with liquids. In addition to dust removal, it also has a cooling effect. Especially suitable for metal dust, aluminum powder and other explosive dust.

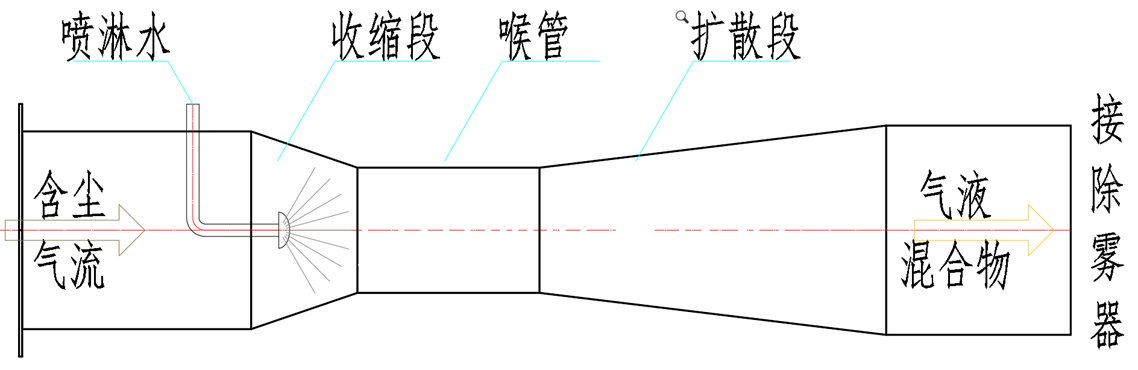

When the gas to be treated passes through the throat of the Venturi tube, a high-speed air flow is generated, which collides with the water sprayed from the throat, causing the water to atomize and mix thoroughly. The dust particles and liquid droplets collide with each other and are moistened, forming large particles and entering the separator for removal. The main structure and principles of the Venturi section are as follows:

The gas humidity reaches saturation and the dust particles are moistened by water. Violent collisions and agglomeration occur between dust particles and liquid droplets or dust particles. In the diffusion section, the gas-liquid velocity decreases, the pressure rises, and the condensation effect with dust particles as condensation nuclei accelerates, condensing into dust-containing droplets with larger diameters, and then being captured in the demister. There are many types of venturi tube structures. According to the cross-sectional shape, it is divided into two types: round and square; according to the adjustability of the throat diameter, it is divided into two categories: adjustable and fixed; according to the liquid atomization method, it can be divided into pre-atomized type and non-atomized type; according to the water supply method, it can be divided into four categories: radial inner spray, radial outer spray, axial water spray and overflow water supply. It is suitable for removing dust particles with a particle size of 0.1-100μm, the dust removal efficiency is 80-99%, the pressure loss range is 1.0-9.0kPa, and the liquid-gas ratio range is 0.3-1.5L/m3.

"Measurement Method for Performance of Wet Dust Collector" (GB/T 15187-2005)

"Comprehensive Emission Standards for Air Pollutants" (GB16297-1996)

"Design Code for Power Distribution of General Electrical Equipment" (GB50055-93)

"Technical Performance and Test Methods of Dust Removal Units" (GB/T 11653-2000)

"Steel surface corrosion grade and rust removal grade before painting" (GB 8923-88)

Since mass transfer and heat transfer occur simultaneously during the contact between gas and liquid, it not only has the function of dust removal, but also has the function of cooling the flue gas and absorbing harmful gases.

1. Dust removal and gas separation, with great operational flexibility and high reliability.

2. Suitable for handling high temperatures. High temperature, flammable, explosive and harmful gases;

3. Normal operation and high purification efficiency;

4. Compact structure, suitable for modification of existing equipment.

5. Exhaust volume measurement;

6. Simple structure, small footprint and low investment;

7. Safe operation, convenient operation and maintenance

Flow meter, liquid level meter, automatic water replenishment valve, high-pressure water pump, adjustable air outlet, demister, water tank, etc.

Fans, explosion-proof devices, online dust detectors, movable water tanks, automatic mud scrapers, PLC touch screen control, network remote control, etc.

Next article:Explosion proof bag filter

-

Welding fume and dust removal project for an auto parts company in Shanghai

Welding fume and dust removal project for an auto parts company in Shanghai -

Vertical filter cartridge dust removal project of a powder industry company in Zhejiang Province

Vertical filter cartridge dust removal project of a powder industry company in Zhejiang Province -

Explosion-proof bag dust removal project for a chemical company in Suzhou

Explosion-proof bag dust removal project for a chemical company in Suzhou -

A case of precision electronic jet Venturi wet dust removal equipment

A case of precision electronic jet Venturi wet dust removal equipment

Current location:

Current location: