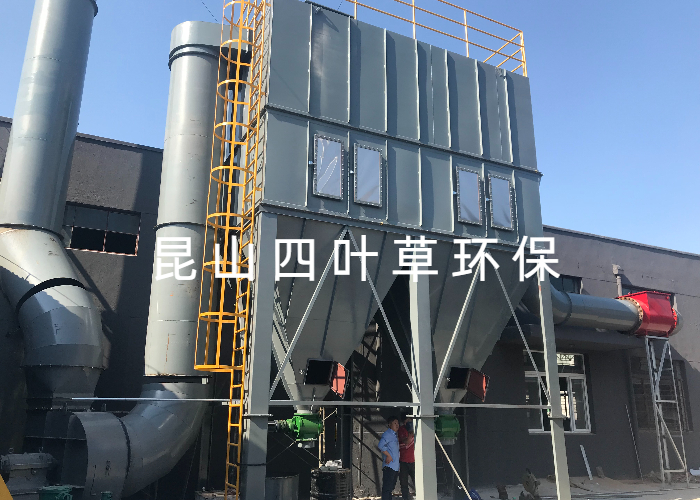

Explosion proof bag filter

|  |

The pulse bag dust collector consists of an upper box, a lower box (cone), a ladder platform, a pulse dust cleaning device, an ash discharge device and an ash storage bucket. It is used for the collection and filtration of various types of dust in industrial production.

On the basis of the above configuration, the explosion-proof filter bag dust collector has added explosion-proof devices, explosion-venting devices, air-locking and ash-unloading devices, cooling devices, self-detection and chain alarm shutdown devices, electrostatic grounding devices, lightning protection devices, etc. It has high safety protection capabilities when dealing with flammable and explosive dusts.

Dusty air enters the bag dust collector from the pipe, and the air penetrates the filter bag from bottom to top, and the heavy dust automatically falls into the silo under the action of gravity. Light dust ions are blocked to the surface of the filter material when passing through the filter bag, and clean air is discharged through the outlet of the dust collector.

The bag dust collector performs online automatic dust cleaning through a pulse device. The dust cleaning device is controlled by a timing controller to perform backflush cleaning at reasonable intervals. After the solenoid valve is opened, the compressed air enters the inside of the filter bag through the blow pipe, thereby shaking the dust on the surface of the bag to the silo.

"Bag dust collector" (JB/T 10341-2002)

"Technical Performance and Test Methods of Dust Removal Units" (GB/T 11653-2000)

"Safety Technical Specifications for Dust Removal Systems for Dust Explosion Hazardous Locations" (AQ4273-2016)

"Design Code for Power Distribution of General Electrical Equipment" (GB50055-93)

"Technical Conditions for General Purpose Centrifugal Ventilators" (JB/T 10563-2006)

"Technical Regulations for Ventilation Ducts" (JGJ 141-2004)

"Steel surface corrosion grade and rust removal grade before painting" (GB 8923-88)

"Dust Explosion Pressure Relief Guide" (GBT15605-2008)

"Code for Design of Electrical Equipment in Explosive Hazardous Environments" (GB50058-2014)

"General Guidelines for Anti-static Accidents" (GB12158-2006)

"Technical Guidelines for Explosion Prevention of Process Equipment in Combustible Dust Workplaces in Industrial and Trade Industries (Trial)"

"Catalogue of Key Combustible Dusts in Industry and Trade" (2015)

"Safety Regulations for Dust Explosion Prevention" (GB15577-2018)

"Code for Lightning Protection Design of Buildings" (GB50057-2010)

"Safety Requirements for Fixed Steel Ladders and Platforms" (GB4053-2009)

"Basic identification colors, identification symbols and safety signs for industrial pipelines" (GB7231-2003)

"Electrical Equipment for Combustible Dust Environments" (GB12476-2013)

"Standards for Determining Hidden Hazards of Major Production Safety Accidents in the Industry and Trade Industry" (Work Safety Supervisor 4 (2017) No. 129)

"Code for Fire Protection Design of Buildings" (GB50016-2014)

Modular design:Provides higher flexibility, you can increase the filtration capacity of the device by adding modules;

Non-pleated bag filter media:Vertical installation makes dust cleaning easier and more thorough, completely avoiding incomplete dust cleaning when the filter cartridge is installed horizontally;

Airflow deflector design:使含尘气流减速、改变方向、沉降效果更好,有效减少含尘气流对滤袋的伤害,延长使用寿命;

布袋式除尘器:相比于滤筒式除尘器应用更加广泛;

自带压差表:易于掌握滤材使用情况,便于把握滤材更换时间;

微电脑脉冲控制:自动在线清灰,因而可进行24小时连续运转;

圆形移动式集灰桶:便于清灰;

傻瓜式控制盘:简单、易操作;

泄爆装置:在捕集易爆性粉尘时,可在发生爆炸时(极不可能发生)最大化的降低破坏程度;

脉冲电磁阀组合:符合IP65及NEMA4要求,可不做任何防护长期在室外使用且功能稳定,如设备在防爆区也可提供满足要求的脉冲电磁阀组合;

多种材质滤材可供选择:可满足不同工况。

除尘效率:可达99.9%

差压表、脉冲电磁阀、爬梯平台、调压阀、脉冲控制仪、布袋,笼骨,锁气卸灰阀

风机、手动插板阀、旋转下料阀、火花捕捉器、泄爆隔爆装置、消防灭火系统、粉尘在线检测仪、螺旋输送机、可移动储灰桶、集成高效过滤器、PLC触摸屏控制、网络远控以及除尘器滤料;

Next article:there is none left

Current location:

Current location: